System configurations

Sewer Robotics rehabilitation robots can be used as a mobile configuration or installed in a van, trailer or box truck as stand-alone system with high pressure unit and water supply.

This economic mobile system configuration is compatible with all SEWER ROBOTICS CRAWLERS and job-specific modules for UHP water jet cutting, lateral reinstatement and CCTV inspection inside 150 – 1000mm (6-40”) pipelines.

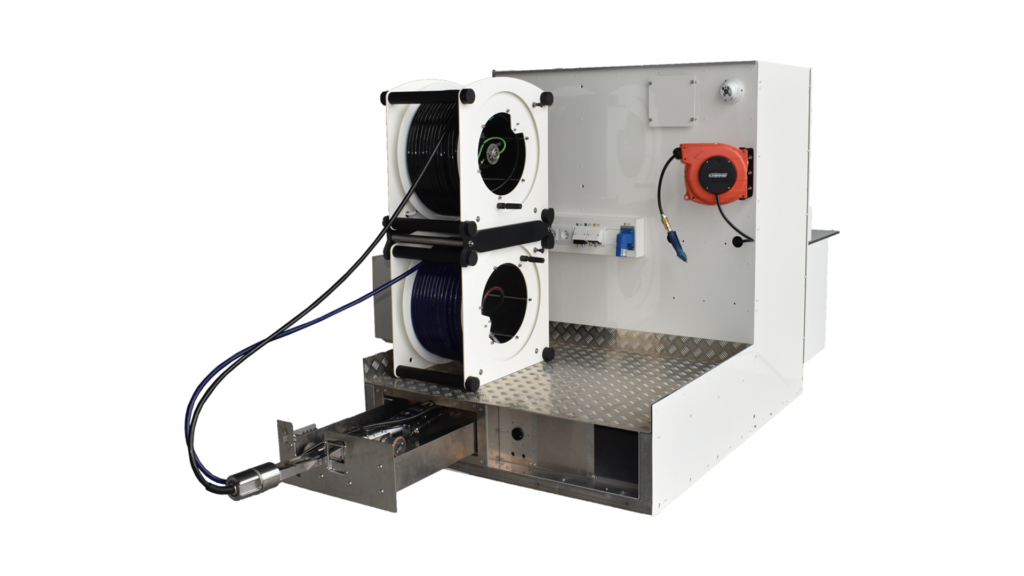

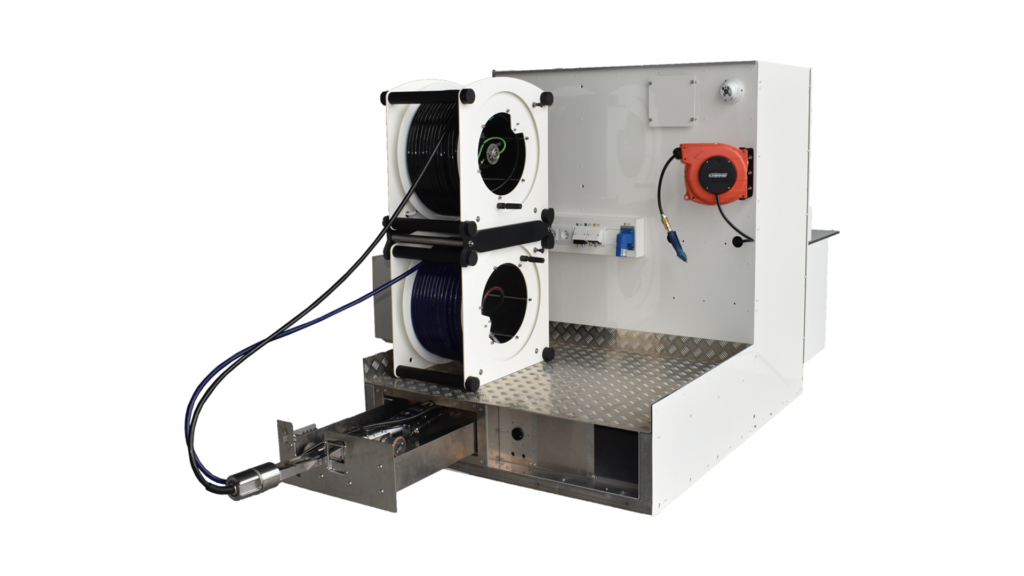

The cable- and hose reels have a small footprint for easement work or installation into any type of vehicle.

PC : 15.6” (1.920 x 1.080) Touch Screen Panel

Joysticks : Dual, 6-axis, responsive joysticks

Interfaces : Robot power supply, communication interface & video interface

Camera : Photo and video capturing with text overlay

Power : 100-230V, 50-60Hz

Dimensions : 540x410x225mm (21.3×16.1×8.7”) – closed

Weight : 18kg (40lbs)

Max. lengths : 120M (400ft)

Max. pressure : 1500bar (21,750psi)

Dimensions : 620x440x620mm (24.4×17.3×24.4”) Stackeable

Weight : 80kg (175lbs)

Compatible Robots : R125, R160, R250, R600, TWK300E

This plug-and-play skid offers a convenient and affordable solution for integrating SEWER ROBOTICS’ lateral reinstatement and precision jet cutting robot systems in vans, trailers and other vehicles.

With a 1000L (264gal) water tank, 3000W power inverter, operator desk with flush mounted joysticks and 27” touch screen PC, rear view camera, and robot storage drawer, it only needs to be anchored inside the vehicle and connected to the vehicle’s batteries.

Compatible reels : HH100 – 120m (400’)

: MH200 – 250m (820’)

Control unit : Flush mounted CP3D joystick panel & 27” Touchscreen PC

Compatible vehicles : Vans, trailers and trucks

Water supply : 1000L (264gal) or more

Power supply : 3000watt 100-230V, 50-60Hz inverter (12-24VDC)

Dimensions : D2400xW 1400xH1620mm (94.5×55.2×64”)

Weight : 340kg (750lbs) (empty tank)

Vehicle GVWR : 3500kg (7,716lbs) with empty tank – or heavier

Compatible Robots : R125, R160, R250, R600, TWK300E

Sewer Robotics box installations have everything exactly at the right place. Reels, robot storage and a workbench in the equipment compartment. Convenient touch screen controls and customizable joysticks, cabinetry with sufficient storage in a laboratory alike control studio and a powerful high-pressure unit with water- and power supplies in the engine room.

BEACONS OR STROBE LIGHTS

WORK LIGHT

REAR VIEW CAMERA

RETRACTABLE WATER &

AIR REELS WITH CLEANING GUNS

JIB CRANE WITH ELECTRIC HOIST

LED lighting

ADDITIONAL MONITOR

HYBRID CABLE REEL

HIGH-PRESSURE HOSE REEL

ROBOT STORAGE DRAWERS

HEATING RADIATOR

SLIDING DOOR TO ACCESS

OPERATOR STUDIO

Clean white wall lining

HAND SANITIZER

WORKBENCH with power receptacles

TOOLS & EQUIPMENT STORAGE

COATED FLOOR

STEP BUMPER

UNDER CARRIAGE STORAGE BOXES

cabinetry

Led lighting

Cctv vicinity camera system

Power receptables

27” Touch sreen pc control unit

Operator desk with flush mounted joysticks

Emergency stop, lighting and system power buttons

Air conditioner

HEATING RADIATOR

Coated floor

Clean White wall lining

Sewer Robotics box installations are built in our factory, with all bells and whistles, to meet

our quality standards and your (custom) requirements.

Such box integrated system is easily shipped inside a container and installed on a suitable

chassis anywhere in the world.

By adding a jetting pump with hydraulic reel, the same precision cutting vehicle and crew can flush removed materials from the obstruction back to the manhole to increase production.

The jetting pump and hose reel can be driven by the same engine or PTO that drives the Ultra High Pressure pump

A third joystick and pneumatic (top-hat) packer controls can be added to enhance operator convenience

Thank you for your online demonstration request.

Your preferred date and time will soon be reviewed and login to the online meeting shared. We are looking forward to meeting you.

Best regards,

Sewer Robotics

info@sewerrobotics.com

+3174 289475

+1 503 504 8474

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |